ABOUT US

Board Ply Trading Sdn Bhd has ventured in the wood supplier business for over 10 years in Malaysia and is also the biggest MGO

Board supplier in Malaysia.

Our wood supply delivers mainly to KL and Selangor but covers the entire map of Malaysia too.

We promised the best quality supply of wood products like plywood, mgo board, chipboard, mdf board, and laminated plywood.

One of Board Ply’s best portfolio is that we supply wood products to the biggest door manufacturer to make fire resistance door.

We are trusted for our effeciency and quality by our clientele from all kind of fields like renovations, furnitures manufacturer,

constructions, hardware shops, architectures, interior designers, developers and more.

Chloride Free MGO Board is also called as Magnesium Sulfate Mgo Board,

is a kind of environmental-friendly board which is widely used in

construction and decoration. It is a new type non-flammable material

made of light weight materials.

Chloride Free MGO Board is made from magnesium oxide, magnesium

sulfate, Wood fiber, Perlite, Small glass cloth and others. the highly

purified MgO is used as the main fireproof material, wood fiber and

perlite are used as filling materials, Without chloride elements, solve the

problems of light corrosion and expansion.

Magnesium Sulfate Mgo Board is fireproof, waterproof, shockproof,

tasteless, non-toxic, ice-free, does not rot, does not crack, deformable,

noncombustible, high strength, light weight, convenient construction, long

service life and has a special performance compound compare with

similar products throughout the country.

Boardply MGO Characteristics Comparison with Similar Materials

What is MGO made of?

Pure magnesium is a silvery metal element (it is shown in the chemistry Periodic Table) and is a solid at room temperature

(unlike mercury, also a metal, which is liquid at room temperature). Magnesium is somewhat like aluminum, but lighter.

The so-called “mag wheels” on sports cars in the ‘60s and ‘70s were actually mostly made of aluminum, but also had some

magnesium in them. Like aluminum, magnesium is usually used in alloy form, particularly for lightweight high

performance structures like airplanes and racecars.

Pure magnesium, in raw form, is not stable–it burns–they make flares and fireworks from it. MGO, however, is the exact

opposite. It is completely non-flammable and used for fireproofing and as furnace liners.

Oxygen, when combined with magnesium under heat and pressure can produce a stone-like material: MGO. MGO exists in

gigantic deposits as raw “rock” and is mined like other minerals. It is ground up into a powder, which is then combined

with water to make a cement-like (adhesive) material. About 70 percent of the world’s MGO is in Asia. Other deposits are

located elsewhere around the globe, but not all have the correct quality for making sheathing. There is sufficient mine-

able MGO spread around the world to make enough “MGO drywall” for centuries. MGO board also contains other

magnesium-based components, but MGO is the main one.

In addition to the base material of MGO, other types of magnesium ‘cements’, wood

flour, and various additives are included to improve manufacturing and enhance

various properties. Most MGO boards have some type of fibrous reinforcement

within the core and/or on the face. Often this takes the form of glass mesh, fibers,

or a fine screed. MGO boards also contain other additives to enhance flexibility and

weather-ability. In other words, there are various types of MGO boards, but most

are essentially the same in terms of their basic composition.

MGO boards are made as individual pieces that are cut to length as they are poured

onto a casting tray. The initial set occurs horizontally, but the final cure occurs

vertically or with spacers between the sheets. The MGO is cast in a liquid slurry-like

form (a mixture of MGO powder, and other additives and water) and sets up by

chemical reaction - much like Portland cement does in stucco or concrete. The cast

boards are then cured at ambient temperature. MGO boards do not contain

asbestos, but some have different types of micro fiber reinforcing. This reinforcing

is separate from the surface scrim, and is part of the MGO slurry used to cast the

MGO sheets.

The use of MGO goes back many centuries, almost to the Pyramids. It was originally used to make mortars for masonry construction.

Nowadays, in many countries, MGO is often used for mortars.

The modern use of MGO to make sheathing panels goes back several decades. MGO boards have been used in Asia and the Middle East

on many large, world-class projects, particularly for partitions and fire walls. This new-to-us type of sheathing has a long, successful

track record.

MGO boards come in various forms. The thinnest boards are about 1/4-inch thick, while the thickest are about an inch. Sheet sizes are

similar to those of drywall.

Various surface finishes are available for MGO board. Some are super smooth and paintable asis, while others are rougher and better

suited for non-aesthetic purposes, such as structural sheathing or a tile backer board, or for the application of thick coatings.

MGO board is a “low tech” and “energy-friendly” product. CO2 is high on the list of “greenhouse” gases, which are said to contribute to

the global warming phenomenon. MGO production is simple, energy efficient, and produces few “greenhouse” gases. This aspect of

MGO, from the standpoint of being a ‘green’/eco-friendly product, would indicate that MGO based products would have a bright future.

In many applications, MGO boards can be used in the same ways as gypsum

and Portland cement sheathings. The substitution is not fully direct in terms of

sheet thicknesses, fastening methods and joint treatments, but is very similar.

This makes MGO board an easy product to use. The possible uses of MGO

board are vast, and some of them include:

• Firewalls.

• Partitions.

• Structural sheathing for wood or metal stud walls.

• Shower stall tile backer board.

• Facings for structural panels engineered to use MGO as the facing.

• Shaft liners.

• Ceilings.

• Soffits.

• Fascia.

• Substrates for coatings and insulated systems (such as Direct-Applied Finish

Systems, EIFS, and stucco).

What is Chloride Free MGO Board

Best Quality Plywood Supplier Company

What Else is in MGO Board?

History of MGO

Possible Uses

Quality Comparison

Product

Boardply MGO Board

Cement Board

Other MGO Board

Gypsum Board

OSB/Plywood

Weight

Low

Hight

Low

Low

High

Flame Resistant

Excellent

Good

Good

Poor

Poor

Water Resistant

Excellent

Good

Good

Poor

Poor

Mould Resistant

Excellent

Good

Excellent

Poor

Poor

Flexibility

Excellent

Poor

Excellent

Poor

Poor

Fasten Strength

Excellent

Poor

Excellent

Poor

Excellent

Environmental

Good

Asbestos Risk

Good

Good

Good

Chloride %

None

Yes

High

None

None

Damp Problem

None

No

In Rainy Day

In Rainy Day

None

Cutting

Knife

Cutting Machine

Knife

Knife

Cutting Machine

Price

Medium

High

Medium

Low

Medium

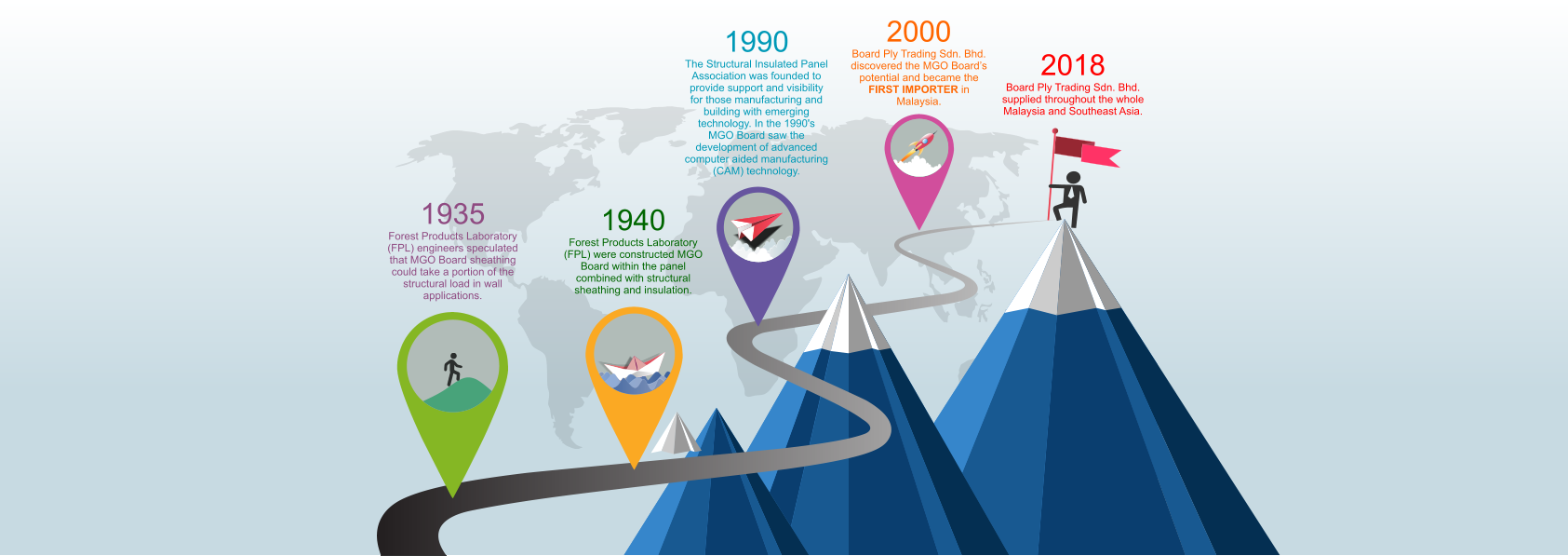

Board Ply MGO Board Milestone

NAVIGATION

SOCIAL

© 2018 Board Ply Trading Sdn. Bhd. All Rights Reserved

CONTACT

Tel: +603-6148 2311

Hotline: +6010-215 2311

Fax: +603-6142 1388

Email: info@boardply.com.my

Website: www.boardply.com.my

ABOUT US

Board Ply Trading Sdn Bhd has ventured in the wood

supplier business for over 10 years in Malaysia and is also

the biggest MGO Board supplier in Malaysia.

Our wood supply delivers mainly to KL and Selangor but

covers the entire map of Malaysia too.

We promised the best quality supply of wood products

like plywood, mgo board, chipboard, mdf board, and

laminated plywood.

One of Board Ply’s best portfolio is that we supply wood

products to the biggest door manufacturer to make fire

resistance door.

We are trusted for our effeciency and quality by our

clientele from all kind of fields like renovations, furnitures

manufacturer, constructions, hardware shops,

architectures, interior designers, developers and more.

Chloride Free MGO Board is also called as Magnesium

Sulfate Mgo Board, is a kind of environmental-friendly

board which is widely used in construction and

decoration. It is a new type non-flammable material

made of light weight materials.

Chloride Free MGO Board is made from magnesium

oxide, magnesium sulfate, Wood fiber, Perlite, Small

glass cloth and others. the highly purified MgO is used

as the main fireproof material, wood fiber and perlite

are used as filling materials, Without chloride elements,

solve the problems of light corrosion and expansion.

Magnesium Sulfate Mgo Board is fireproof, waterproof,

shockproof, tasteless, non-toxic, ice-free, does not rot,

does not crack, deformable, noncombustible, high

strength, light weight, convenient construction, long

service life and has a special performance compound

compare with similar products throughout the country.

What is MGO made of?

Pure magnesium is a silvery metal element (it is shown in the

chemistry Periodic Table) and is a solid at room temperature

(unlike mercury, also a metal, which is liquid at room

temperature). Magnesium is somewhat like aluminum, but

lighter. The so-called “mag wheels” on sports cars in the ‘60s

and ‘70s were actually mostly made of aluminum, but also

had some magnesium in them. Like aluminum, magnesium is

usually used in alloy form, particularly for lightweight high

performance structures like airplanes and racecars.

Pure magnesium, in raw form, is not stable–it burns–they

make flares and fireworks from it. MGO, however, is the exact

opposite. It is completely non-flammable and used for

fireproofing and as furnace liners.

Oxygen, when combined with magnesium under heat and

pressure can produce a stone-like material: MGO. MGO exists

in gigantic deposits as raw “rock” and is mined like other

minerals. It is ground up into a powder, which is then

combined with water to make a cement-like (adhesive)

material. About 70 percent of the world’s MGO is in Asia.

Other deposits are located elsewhere around the globe, but

not all have the correct quality for making sheathing. There is

sufficient mine-able MGO spread around the world to make

enough “MGO drywall” for centuries. MGO board also

contains other magnesium-based components, but MGO is

the main one.

In addition to the base material of MGO, other types of

magnesium ‘cements’, wood flour, and various additives are

included to improve manufacturing and enhance various

properties. Most MGO boards have some type of fibrous

reinforcement within the core and/or on the face. Often

this takes the form of glass mesh, fibers, or a fine screed.

MGO boards also contain other additives to enhance

flexibility and weather-ability. In other words, there are

various types of MGO boards, but most are essentially the

same in terms of their basic composition.

MGO boards are made as individual pieces that are cut to

length as they are poured onto a casting tray. The initial set

occurs horizontally, but the final cure occurs vertically or

with spacers between the sheets. The MGO is cast in a

liquid slurry-like form (a mixture of MGO powder, and other

additives and water) and sets up by chemical reaction -

much like Portland cement does in stucco or concrete. The

cast boards are then cured at ambient temperature. MGO

boards do not contain asbestos, but some have different

types of micro fiber reinforcing. This reinforcing is separate

from the surface scrim, and is part of the MGO slurry used

to cast the MGO sheets.

The use of MGO goes back many centuries, almost to

the Pyramids. It was originally used to make mortars for

masonry construction. Nowadays, in many countries,

MGO is often used for mortars.

The modern use of MGO to make sheathing panels

goes back several decades. MGO boards have been

used in Asia and the Middle East on many large, world-

class projects, particularly for partitions and fire walls.

This new-to-us type of sheathing has a long, successful

track record.

MGO boards come in various forms. The thinnest

boards are about 1/4-inch thick, while the thickest are

about an inch. Sheet sizes are similar to those of

drywall.

Various surface finishes are available for MGO board.

Some are super smooth and paintable asis, while

others are rougher and better suited for non-aesthetic

purposes, such as structural sheathing or a tile backer

board, or for the application of thick coatings.

MGO board is a “low tech” and “energy-friendly”

product. CO2 is high on the list of “greenhouse” gases,

which are said to contribute to the global warming

phenomenon. MGO production is simple, energy

efficient, and produces few “greenhouse” gases. This

aspect of MGO, from the standpoint of being a

‘green’/eco-friendly product, would indicate that MGO

based products would have a bright future.

In many applications, MGO boards can be used in the

same ways as gypsum and Portland cement sheathings.

The substitution is not fully direct in terms of sheet

thicknesses, fastening methods and joint treatments, but

is very similar. This makes MGO board an easy product to

use. The possible uses of MGO board are vast, and some

of them include:

• Firewalls.

• Partitions.

• Structural sheathing for wood or metal stud walls.

• Shower stall tile backer board.

• Facings for structural panels engineered to use MGO as

the facing.

• Shaft liners.

• Ceilings.

• Soffits.

• Fascia.

• Substrates for coatings and insulated systems (such as

Direct-Applied Finish Systems, EIFS, and stucco).

What is Chloride Free MGO Board

Best Quality Plywood Supplier Company

What Else is in MGO Board?

History of MGO

Possible Uses

Quality Comparison

Board Ply MGO Board Milestone

NAVIGATION

© 2018 Board Ply Trading Sdn. Bhd. All Rights Reserved

CONTACT

Tel: +603-6148 2311

Hotline: +6010-215 2311

Fax: +603-6142 1388

Email: info@boardply.com.my

Website: www.boardply.com.my